Workbench Part 2

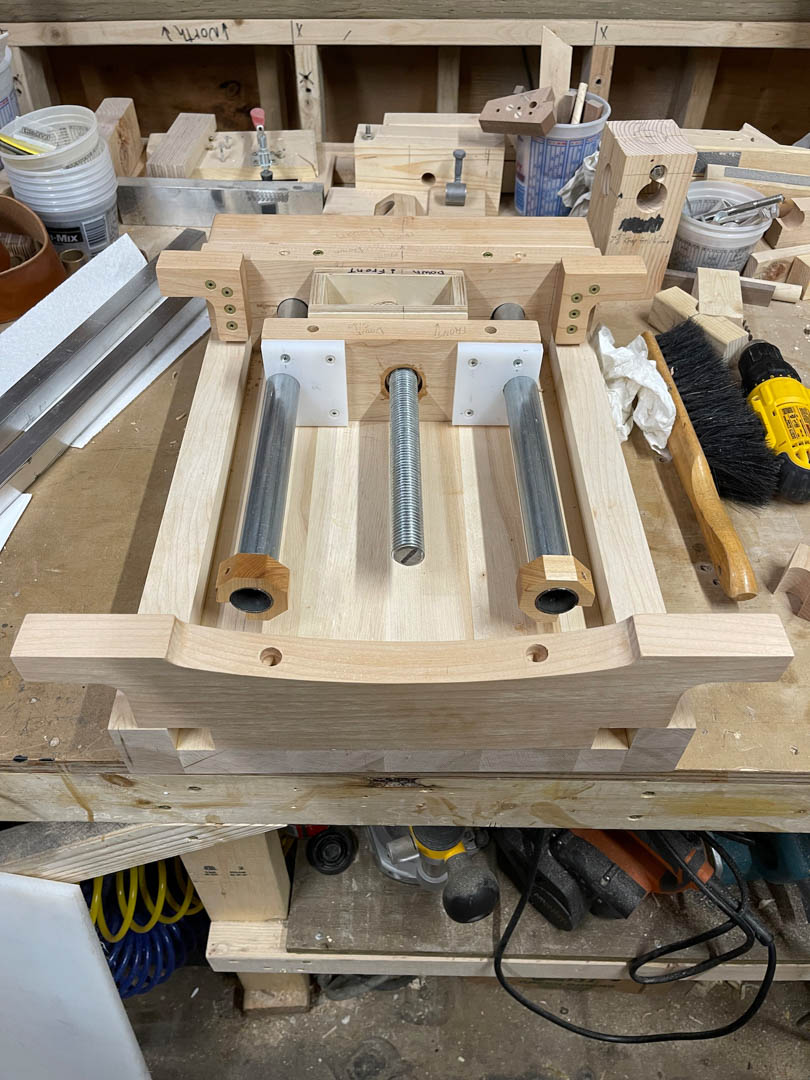

Continuing with the build; getting close to the finish. Still have some details with the vise and then the next step will be the top extension. First on the detail list are some guides for the front jaw guide tubing. I had some UHMW scraps that will do nicely but the hole required is just slightly over any standard drill bit size. Solution was to drill out to the closest size and use the tubing to ream it out to the perfect fit. It was a lot easier to make the tool than I expected. Just some short hack saw cuts and very little filing. I had to tweak each “tooth” slightly but this was easy to do with needle nose pliers. In the background is a 1″ sanding drum which fit nicely inside the tubing and enabled me to chuck it up in a drill.

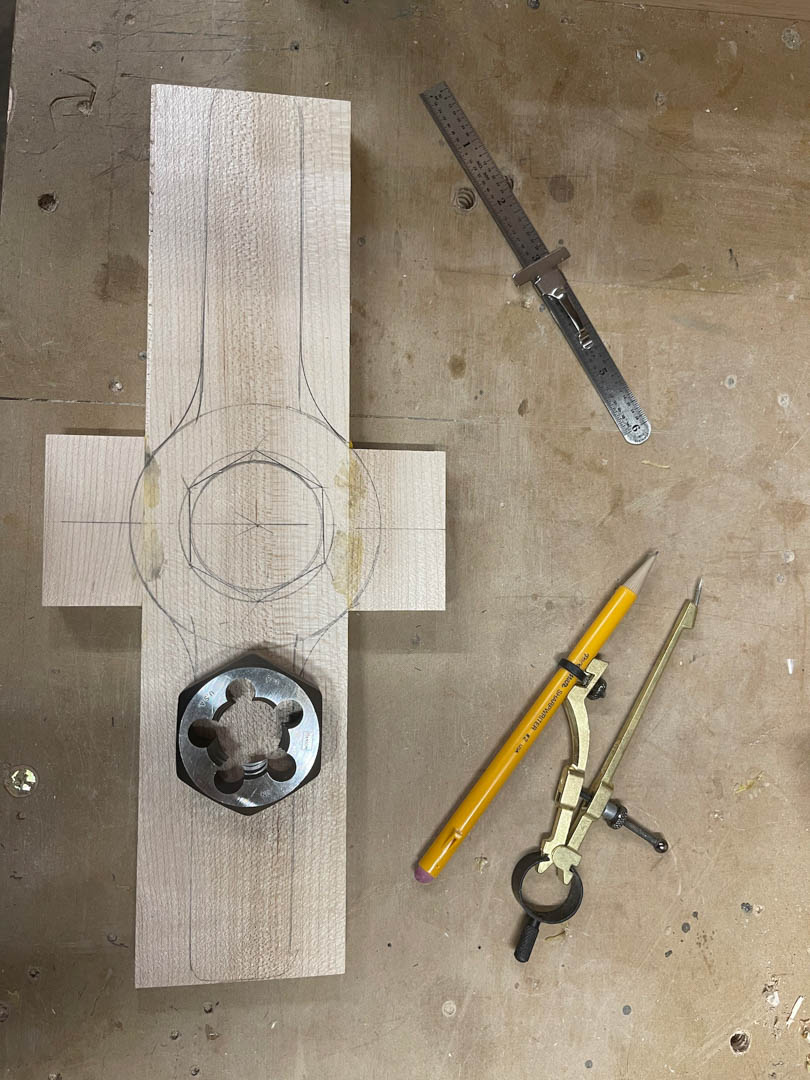

Next, make the handle for the vise. I cut some 1″ nuts out of maple and ran a die through them. The first try resulted in nuts that were crooked. Normally, I would put the die in the drill press but the shank of the die was too big for that so I decided to make a die wrench out of maple.

I taped a bullseye level to a piece of maple and set a magnet in the underside. Then I could set the wood up nice and level in the bench vise and then put it on the die wrench for the cutting.

That worked! Next I needed to cut threads in the dowel so a handle was necessary for the die.

Here’s the set. Much cheaper than buying wrenches for each; that is possibly a first.

The die handle worked well but even after soaking the dowel end in Linseed oil overnight a lot of the threads broke off in the cutting process. The problem is that the grain is perpendicular to the cut. I decided to try making saw cuts across the dowel and then filling them in with epoxy to hold it all together. Here’s how that looked.

The die handle worked well but even after soaking the dowel end in Linseed oil overnight a lot of the threads broke off in the cutting process. The problem is that the grain is perpendicular to the cut. I decided to try making saw cuts across the dowel and then filling them in with epoxy to hold it all together. Here’s how that looked.

Above is the dowel end still in the block I used as a mold to contain the epoxy. Below is the reinforced dowel before threading.

Below is the other end of the dowel (with no epoxy) after threading. Ugg.

I don’t have a picture of the epoxy reinforced end after threading because they look exactly the same. Double Ugg! I’m going to use it anyway as this is something I can easily replace later. I’m open to any suggestions. I’m thinking of trying an Ebony or Ironwood dowel. Possibly solid epoxy for the entire threaded area. It will be something to play with in the lab.

Getting closer to the end of the tunnel. No trains yet.

So, I spent all day yesterday sanding and drilling the holes for the bench dogs.

Not that bench dog. The dogs on the bench in this picture.

Yes it is finished. I put leather on the vise jaws and made the stops for the extension. With it fully expanded it will hold a board over 42″ long. The white tube sticking out of the front vise jaw is the tool for changing the extension.

The short section of dowel with the sawed off bolt are the locking pins. You just put them in any set of outside dog holes and pull the extension out until they drop into the hole you see in the middle hole above. That hole is in the top of the 1″ square aluminum tubing that is attached to the extension. In the picture previous to this one the extension is locked into the third set of holes. You can just see the tops of the bolts. The white tubing has a magnet for pulling the locking pins out of the holes. The picture below shows the extension fully retracted and the vise jaws closed.

The handle is too long but I’m not cutting it down until I solve the threading problem. And, I still need to fine tune the feet as there is a slight wobble. That involves winding sticks and enough room to back up and sight in on them. For now it is going on tour for a few days.

Then I can get back to the next projects, the outhouse posts and drafting plans for a roof over a deck.

Unusual weather lately. Lots of rain; forecast has highs in the 40’s and rain for the next five days. I killed my first February mosquito the other day. Don’t think I’ve seen a mosquito in February in my 30 years here. So he had to die, even if the mosquito is our first bird of Spring. This is all happening two months early, so I’m thinking it is a trap.

For now, perfect weather for drafting.

Leave a Reply